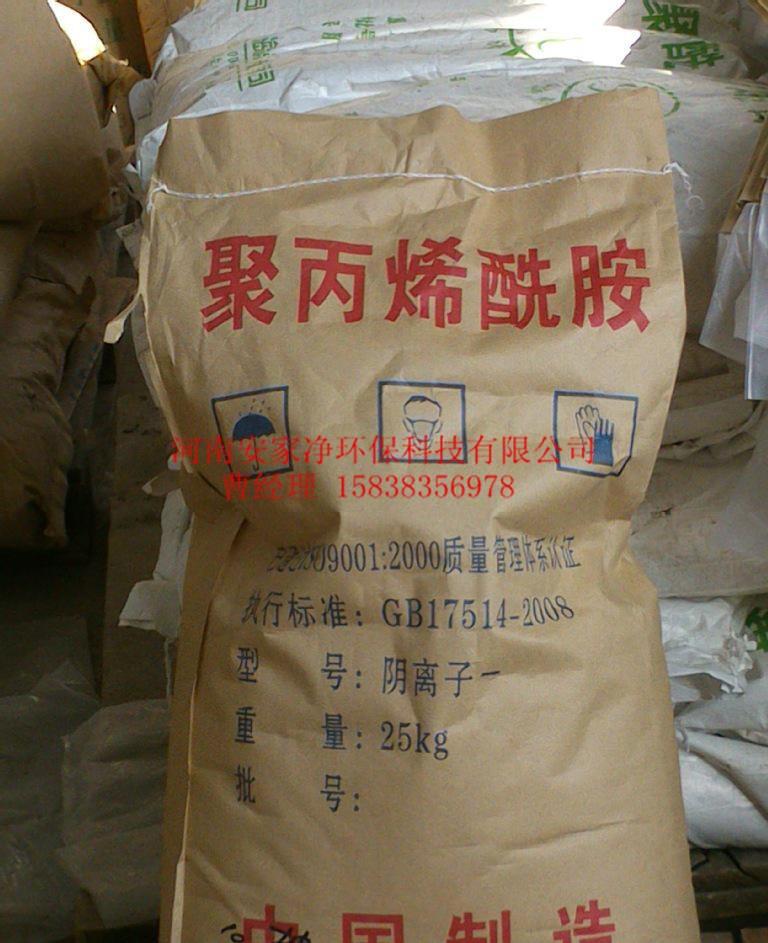

湖州生活废水阳离子聚丙烯酰胺pam沉淀剂絮凝剂洗沙压滤剂聚合氯化铝pac价格让利

产品价格:¥12000(人民币)

商铺名称:河南安家净环保有限公司

联系人:曹经理(先生)

联系手机:

固定电话:

企业邮箱:1090222013@qq.com

联系地址:河南巩义永安路经济开发区

邮编:

联系我时,请说是在勒克斯之家上看到的,谢谢!

商品详情

阴离子聚丙烯酰胺水解度越高越好吗?其实这个问题太抽象了,阴离子聚丙烯酰胺不一定水解度越高就好;应该关于某类型的污水,阴离子挑选哪种水解度的适宜。 咱们先了解一下,阴离子聚丙烯酰胺 的制备与那些道治理用的除磷剂是对城市水源水混凝除浊处理及除磷的物品。可以在对城市水源水混凝除浊处理同时,到达深度除磷意图。

从而将处理后饮用水中的磷含量降至界限值以下,不需要改动原水处理流程,不需要增设大型水处理构筑物,简便易行,经济实用,可获得显著的社会和经济效益。

河道治理用的除磷剂运用方法量投加不会造成不良影响的,毕竟铁也是微生物生长所需要的微量元素。但是如果投加量过大,则会使污泥活性收到影响,还有疑问可以到环保.通交流。

生化末端 没有影响,何况少量的铁盐能够对Phosphorus removal agent for road treatment is a kind of material for coagulation and turbidity removal of urban water source and phosphorus removal. It can reach the intent of deep dephosphorization at the same time of coagulation and turbidity removal of urban water source.

Thus, the phosphorus content in treated drinking water can be reduced to below the threshold value, without changing the original water treatment process, without adding large water treatment structures, which is simple, economical and practical, and can achieve remarkable social and economic benefits.

The amount of phosphorus removal agent used in river regulation will not cause adverse effects. After all, iron is also a trace element needed for microbial growth. However, if the dosage is too large, the sludge activity will be affected. There are still doubts about environmental protection and communication.

There is no effect on the biochemical end, let alone a small amount of iron salts.

悬浮物上漂

1、操作不当,有的是不专业的人员在实验中运用了不当手法,加入聚合氯化铝后,搅拌过急过慢都不行,初次实验,要有专业的水处理师从旁协助,这是很重要的一点。

2、加聚合硫酸铁的量没有控制好,(加药过多或过少)这种情况,最容易出现悬浮物上漂。

使用前,将本产品按一定浓度(10-30%)投入溶矾池,注入自来水搅拌使之充分水解,静置至呈红棕色液体,再兑水稀释到所需浓度投加混凝。水厂亦可配成2-5%直接投加,工业废水处理直接配 成5-10%投加。 b、投加量的确定,根据原水性质可通过生产调试或烧杯实验视矾花形成适量而定,制水厂可以原用的其它药剂量作为参考,在同等条件下本产品与固体聚合氯化铝用量大体相当,是固体硫酸铝用量的 1/3-1/4。如果原用的是液体产品,可根据相应药剂浓度计算酌定。大致按重量比1:3而定。

关于污水处理使用聚合硫酸铁上水层出现漂浮物的原因以及解决方法

污水处理1. Improper operation, some non-professional personnel in the experiment used improper techniques, adding polyaluminium chloride, stirring too fast or too slow can not, the first experiment, there must be professional water treatment assistant, this is a very important point.

2. The amount of polyferric sulfate added is not well controlled (too much or too little dosage). In this case, suspended solids are most likely to float.

Before use, the product was put into the alum bath at a certain concentration (10-30%) and stirred with tap water to make it fully hydrolyzed. The product was put into a red-brown liquid and diluted with water until the required concentration was added and coagulated. Waterworks can also be added 2-5% directly, and industrial wastewater treatment can be added 5-10%. B. The determination of dosage depends on the proper amount of alum formed by production debugging or beaker experiment according to the nature of raw water. The other dosage used in water plant can be used as reference. Under the same conditions, the dosage of this product is approximately equal to that of solid polyaluminium chloride, which is 1/3-1/4 of that of solid aluminium sulfate. If the original liquid product is used, it can be calculated according to the concentration of the corresponding agent. It depends roughly on the weight ratio of 1:3.

Reasons and Solutions for Floating Matter in the Upper Water Layer of Polyferric Sulfate Used in Sewage Treatment

3、加聚合硫酸铁的量对了,但是废水的PH值不对,没有在相应药剂的使用PH范围。适应水体PH值范围宽为4-11,H值范围为6-9,净化后原水的PH值与总碱度变化幅度小

4、使用净水产品的型号不对,根据污水的特点,选择适合自己污水特征的净水剂,如:聚合氯化铝、聚氯化铝、聚合氯化铝铁、氯化铝、喷雾式聚合氯化铝、白色聚合氯化铝等等,听从专业水处理师的指导意见,他们给的意见都是专业性的。

关于污水处理使用聚合硫酸铁上水层出现漂浮物的原因以及解决方法

聚合硫酸铁

5、最后一点要考虑的就是,你所使用的聚合硫酸铁,质量是否达标,聚合硫酸铁的各项指标是否符合标准。

现在市面上聚合硫酸铁的质量参差不齐,相对于质量好一些的聚合硫酸铁在使用过程中,出现悬浮物的几率会很低的,好一些的聚合硫酸铁几乎是没有水不溶物的,所以产品质量也是非常重要。微生物活性有促进作用,就是出水色度有影响

将化学除磷剂投加于生化池的后面,这样便可以完全避免水中多种物质与除磷剂发生反应,消耗药剂用量.且不会降低生化池的进水有机碳浓度,影响微生物的脱氮除磷效果。同时还可避免过多投加除磷剂,也会使残余的药剂进入生化系统中,对微生物生长造成影响。

将除磷絮凝剂投加于好氧池的出水口端,二沉池的前面投加除磷剂则可以大量减少除磷药剂的使用量,这是废水在生化处理的过程中已去除水中大部分磷,并将偏磷、有机磷转化为可通过混凝处理的正磷,大大提高除磷效果和减少除磷剂投加量,减少污泥产量、减少污泥中的磷含量。 所以,化学除磷药剂一般投加于生化后,二沉池前,节省废水除磷成本和提高达标率。?

运用时可将本产品直接投加,或先参加溶解罐,浓度为10~20%,拌和,用泵投加到反响池。本产品适用的pH值规模广,在酸性条件下运用效果尤佳,运用量约为100~1000ppm(即0.1~1公斤/吨废水),依据废水中磷酸根的含量不同其用量有所差异,详细用量一般通过试验断定。

试验时取一定量的原水,参加适量的本产品(如500ppm),将废水pH值调节至7~8,www.hnldscl.com参加少数聚丙烯酰胺PAM絮凝沉积,过滤取上清液测定磷的含量。(如需处理重金属,用上清液进行二次处理即可。)AC/PAM与除磷剂搅拌后的反应?使用时可将本产品直接投加,或先参加溶解罐,浓度为10~20%,拌和,用泵投加到反响池。本产品适用的pH值规模广,在酸性条件下使用作用尤佳,使用量约为100~1000ppm(即0.1~1公斤/吨废水),依据废水中磷酸根的含量不同其用量有所差异,具体用量一般经过试验断定。The amount of polyferric sulfate added is right, but the PH value of wastewater is not right, and there is no optimum range of PH used in the corresponding reagents. The suitable range of PH value is 4-11, and the optimum range of PH value is 6-9. After purification, the change range of PH value and total alkalinity of raw water is small.

4, the type of water purification products is not correct. According to the characteristics of sewage, choose suitable water purifying agent suitable for its own sewage characteristics, such as polyaluminum chloride, polyaluminum chloride, polyaluminum ferric chloride, aluminum chloride, spray polyaluminum chloride, white polyaluminium chloride, etc., and listen to the advice of professional water treatment division, and give their advice. They are all professional.

Reasons and Solutions for Floating Matter in the Upper Water Layer of Polyferric Sulfate Used in Sewage Treatment

Polyferric sulfate

5. The last point to consider is whether the quality of the polyferric sulfate you use meets the national standards, and whether the various indicators of the polyferric sulfate meet the national standards.

At present, the quality of polyferric sulfate is uneven in the market. Compared with the better quality of Polyferric sulfate, the probability of suspended solids will be very low. The better polyferric sulfate has almost no water insoluble solids, so the quality of products is also very important. Microbial activity has a promotive effect, that is, effluent color has an impact.

Adding chemical Dephosphorizer to the back of biochemical pond can completely avoid the reaction between various substances in water and dephosphorizer, consume the amount of reagent, and will not reduce the concentration of organic carbon in the influent of biochemical pond, affecting the effect of nitrogen and phosphorus removal by microorganisms. At the same time, it can avoid excessive dosage of phosphorus removal agents, and also make the residual agents into the biochemical system, which will affect the growth of microorganisms.

Adding phosphorus removal flocculant to the outlet of aerobic tank and phosphorus removal agent in front of secondary sedimentation tank can greatly reduce the use of phosphorus removal agent. This is because most phosphorus in wastewater has been removed in the process of biochemical treatment, and phosphorus migration and organic phosphorus are converted into positive phosphorus which can be treated by coagulation, which greatly improves the effect of phosphorus removal and improves the efficiency of phosphorus removal. Reduce the dosage of phosphorus removal agent, reduce sludge production, reduce phosphorus content in sludge. Therefore, chemical phosphorus removal agents are generally added to the biochemical process, before the secondary sedimentation tank, to save the cost of phosphorus removal from wastewater and improve the rate of reaching the standard. ?

When in use, the product can be directly added or participated in the dissolving tank, the concentration of which is 10-20%, mixed and pumped into the reaction tank. The product is suitable for a wide range of pH values, especially in acidic conditions. Its application amount is about 100-1000 ppm (i.e. 0.1-1 kg/ton wastewater). According to the different content of phosphate in wastewater, its dosage is different. The detailed dosage is generally determined by experiments.

During the experiment, a certain amount of raw water was taken and the product (such as 500 ppm) was added. The pH value of the wastewater was adjusted to 7-8. www.hnldscl.com participated in the flocculation and deposition of a few PAM. The supernatant was filtered to determine the phosphorus content. (If heavy metals need to be treated, the supernatant can be used for secondary treatment.) Reaction of AC/PAM with phosphorus removal agent after stirring? When in use, the product can be directly added or participated in the dissolving tank at the concentration of 10-20%. The product can be mixed and pumped into the reaction tank. The product is suitable for a wide range of pH values, especially in acidic conditions. Its usage is about 100-1000ppm (i.e. 0.1-1 kg/ton wastewater). According to the content of phosphate in wastewater, its dosage is different. The specific dosage is generally determined by experiments.

试验时取一定量的原水,参加适量的本产品(如500ppm),将废水pH值调理至7~8,参加少数聚丙烯酰胺PAM絮凝沉积,过滤取上清液测定磷的含量。(如需处理重金属,用上清液进行二次处理即可。) FeCl3、及 AlCl3溶液充沛混合均匀后参加NaOH溶液,三者摩尔比为3∶2∶14;混合反响并静置后滤出生成物,用水重复洗刷至出水为中性;于100-110℃下烘干并制成尺度均匀的粒状吸附剂。

该吸附剂的使用,在惯例水处理工艺中增设吸附除磷工艺,吸附除磷工艺由2-4个串联运转的除磷吸附池组成,除磷吸附池结构同滤池,用粒状复合铁铝除磷吸附剂作滤料,粒径规模0.5mm-0.8mm,吸附层厚度为1.0-1.5m,吸附池水力负荷5m/h-8m/h,空床触摸时刻30-40min。该吸附剂除磷适用规模广;除污染效能优异,再生简略,质料价格低,易得安全。

PAC/PAM与除磷剂制备办法

FeCl3及 AlCl3溶液充沛混合均匀后参加NaOH溶液,三者摩尔比为3∶2∶14;混合反响并静置后滤出生成w物,用水重复洗刷至出水为中性;于100-110℃下烘干并制成尺度均匀的粒状吸附剂。

该吸附剂的使用,在惯例水处理工艺中增设吸附除磷工艺,吸附除磷工艺由2-4个串联运转的除磷吸附池组成,除磷吸附池结构同滤池,用粒状复合铁铝除磷吸附剂作滤料,粒径规模0.5mm-0.8mm,吸附层厚度为1.0-1.5m,吸附池水力负荷5m/h-8m/h,空床触摸时刻30-40min。该吸附剂除磷适用规模广;除污染效能优异,再生简略,质料价格低,易得安In the experiment, a certain amount of raw water was taken and the product (e.g. 500 ppm) was participated in. The pH value of wastewater was adjusted to 7-8. A few PAM flocculating deposits were participated in. The content of phosphorus in the supernatant was determined by filtration. (If heavy metals need to be treated, the supernatant can be used for secondary treatment.) FeCl3, AlCl3 and AlCl3 solutions were mixed in NaOH solution with a molar ratio of 3:2:14; the product was filtered after mixing reaction and standing, and washed repeatedly with water until the effluent was neutral; the granular adsorbent was dried at 100-110 ~C and made into uniform size.

The adsorbent is used to remove phosphorus by adsorption in conventional water treatment process. The adsorbent consists of 2-4 series operation phosphorus removal adsorbents. The structure of the adsorbent is the same as that of the filter. The particle size of the adsorbent is 0.5mm-0.8mm, the thickness of the adsorbent layer is 1.0-1.5m, and the hydraulic force of the adsorbent is negative. Load 5 m/h-8 m/h, empty bed touching time 30-40 min. The adsorbent has wide application scale for phosphorus removal, excellent pollution removal efficiency, simple regeneration, low material price and easy to obtain safety.

Preparation of PAC/PAM and Phosphorus Removal Agent

FeCl3 and AlCl3 solutions were mixed in NaOH solution with a molar ratio of 3:2:14. After mixing and standing, W was filtered and washed repeatedly with water until the effluent was neutral. The granular adsorbent was dried at 100-110 C and made into uniform size.

The adsorbent is used to remove phosphorus by adsorption in conventional water treatment process. The adsorbent consists of 2-4 series operation phosphorus removal adsorbents. The structure of the adsorbent is the same as that of the filter. The particle size of the adsorbent is 0.5mm-0.8mm, the thickness of the adsorbent layer is 1.0-1.5m, and the hydraulic force of the adsorbent is negative. Load 5 m/h-8 m/h, empty bed touching time 30-40 min. The adsorbent is suitable for phosphorus removal on a wide scale, with excellent pollution removal efficiency, simple regeneration, low material price and easy access to safety.

FeCl3、及 AlCl3溶液充分混合均匀后参加NaOH溶液,三者摩尔比为3∶2∶14;混合反响并静置后滤出生成物,用水反复洗刷至出水为中性;于100-110℃下烘干并制成尺度均匀的粒状吸附剂。该吸附剂的使用,在常规水处理工艺中增设吸附除磷工艺,吸附除磷工艺由2-4个串联运转的除磷吸附池组成,除磷吸附池结构同滤池,用粒状复合铁铝除磷吸附剂作滤料,粒径规模0.5mm-0.8mm,吸附层厚度为1.0-1.5m,吸附池水力负荷5m/h-8m/h,空床触摸时间30-40min。该吸附剂除磷适用规模广;除污染效能优异,再生简单,质料价格低,易得安全。

河道治理用的除磷剂适用规模

1、用于生活污水处理厂除磷,特别是合适中磷段污水处理;

2、合适于含外表处理工艺的工业废水;

3、用于食品厂废水;

4、用于制药、造纸、农药、化肥厂的废水处理。

5、用于废物填埋厂废物渗滤液处理。After fully mixing and homogenizing AlCl3 solution, NaOH solution was added with a molar ratio of 3:2:14; the product was filtered after mixing and standing, and washed repeatedly with water until the effluent was neutral; the granular adsorbent was dried at 100-110 (?) C and made into uniform size. The adsorbent is used to remove phosphorus by adsorption in conventional water treatment process. The adsorbent consists of 2-4 series operation phosphorus removal adsorbents. The structure of the adsorbent is the same as that of the filter. The particle size of the adsorbent is 0.5mm-0.8mm, the thickness of the adsorbent layer is 1.0-1.5m, and the hydraulic force of the adsorbent is negative. Load 5 m/h-8 m/h, empty bed touch time 30-40 min. The adsorbent has wide application scale for phosphorus removal, excellent pollution removal efficiency, simple regeneration, low material price and easy safety.

Application Scale of Phosphorus Removal Agents for River Regulation

1. It is used for phosphorus removal in domestic sewage treatment plants, especially for medium phosphorus section sewage treatment.

2. Suitable for industrial wastewater containing surface treatment process.

3. Wastewater from food factories;

4. Wastewater treatment in pharmaceutical, papermaking, pesticide and fertilizer plants.

5. Waste leachate treatment in waste landfill plants.

聚丙烯酰胺工业用处:聚丙烯酸胺(PAM)分子量高、水溶性好、可调理分子量,并能够引进各种离子基团以得到特定的性能。低分子量是分散资料有效增调剂或稳定剂,高分子量是重要的絮凝剂,它能够制造出亲水而水不溶性的凝胶,它对许多团体外表和溶解物质有良可以作为净水药剂使用,也可以在造纸领域被当做助留剂使用,部分造纸使用草浆纤维较短,细胞杂质较高,导致了纸张强度较差,抄纸过程中滤水困难。对于此问题处理办法有两种:机械截留和胶体絮凝。

机械截留类似于过滤作用,它适用于纸张中较长部分纤维,纤细组分隐藏高的原因无法由此说明,助留剂的助留作用也无法用此解释;

胶体絮凝作用为:凝聚作用和絮凝作用。分子量较小或者无机盐、电荷密度较高的聚合物使胶体悬浮液稳定性丧失从而发生絮聚作用称之为凝聚作用,经过电荷中和、异相凝聚和补缀作用几种方法产生的沉积物。聚合氯化铝是指聚凝作用中所提到的无机盐。电荷密度较高的聚合物。

运用聚合氯化铝处理了造纸进程由酸性改为中、碱性规模,纸浆中的阴离子杂质的问题,纸机操作以及纸质量的一系列问题,聚合氯化铝带有阳电荷,可以有效的控制阴离子的作用,有利于纸张滤水性 改善,聚合氯化铝极容易在纤维外表形成吸附,还可以将带有负电荷的填料和纤维吸附,使细料的藏着率有效的提高,浆料的滤水功效得到进一步的改善好的粘附力。由于以上性能PAM普遍应用于絮凝、增稠、减阻、拟胶、粘结、阻垢等范畴 。

阴离子聚丙烯酰胺依据不同用处和用户对产品性能的央求,可选用不同分子量运用。

在工业废水处置中,特别是关于悬浮颗粒、较粗、浓度高、粒子带阳电荷,水的PH值为中性工碱性的污水如钢铁厂废水,电镀厂废水,冶金废水,洗煤废水等污水处置效果很好。

在饮用水处置。我国很多自来水厂的水源自江河泥少及矿物质含量高,比拟混浊,虽经过沉淀处置,但仍达不到央求,需求投加絮凝剂,才干使水质变清,很多自来水厂采用无机絮凝剂,但投加量大,构成污泥量增大效果不好,采用阴离子聚丙烯酰胺作絮凝剂,投加量是无机絮凝的50分之一但效果是无机絮凝剂的几倍至几十倍,特别是我公司消费的聚丙烯酰胺,剩余单体已抵达食品级(小于0.05%),接近国外先进程度,,对处置饮用水更为合适,关于有机物污染严重的江河水和阴离子聚丙烯酰胺配合运用效果更好。

聚丙烯酰胺用作淀粉厂及酒精厂的流失淀粉及酒糟的回收。往常很多淀粉厂排出的废水内淀粉很高,排放之后影响环境,糜费资源,投加PAM,使淀粉沉淀,沉淀物经压滤机压滤变成饼类可作饲料,酒精厂大量的酒糟就是采用这种工艺加工的,黑龙江某酒精厂就是聚丙烯酰胺作絮凝剂,对酒糟中止回收的而且获得了很大的经济效益。

聚丙烯酰胺用作油田调剖堵水的堵水剂,三次采油的驱油剂。

聚丙烯酰胺用作造纸助剂,PAM在造纸方面用处很普遍,可作为长纤维造纸分散剂,干湿加强剂,助留,助滤剂及造纸废水的絮凝剂等。

最新型的水处置剂聚丙烯酰胺,在很多场所处置污水和上水时,阴离子聚丙烯酰胺和阳离子聚丙烯酰胺配合运用要比单独运用一种离子型聚丙烯酰胺产生十分显著和协同效应,PAM对降低外表张力的才干要远远大于同条件下阳离子或阴离子单独存在的才干,为抵达降低外表张力的央求,需求同时运用阴离子和阳离子聚丙烯酰胺,便两者如运用不当,会产生白色沉淀物,失去运用效果 。而PAM具有两性离子的特性,它能够完成阴离子、阳离子的配合协同作用,面没有任何沉淀物的产生,特别是对水质状况比拟复杂或水的性质经常变化的,运用PAM作为处置絮凝剂更为便当,效果更好。

在污水预处置中采用的污泥取自以钱塘江水为水源的沉淀池,该水厂以聚合氯化铝PAC为絮凝剂。污泥经自然浓缩到含固率为2.7%~2.8%,经测定,污泥中有机物含量为12.1%,sj如含量为52.1%,Al。含量为20.2%。 PAM有阳离子型、阴离子型和非离子型三品种型。非离子型PAM溶解速度较慢,普通不用于污泥预处置,因而实验仅选用两种有代表性的阳离子聚丙烯酰胺和阴离子聚丙烯酰胺。阳离子型PAM分子量1200万,丙烯酰胺单体含量0.012%。阴离子型PAM分子量1250万,丙烯酰胺单体含量0.013%。两种PAM配制浓度均为0.05%%,冰箱冷藏24h后运用。

(1)PAM预处置污泥取lOOml污泥,放入300ml的烧杯中,采用六联搅拌机以1130rpm的转速快 速搅拌30s后疾速投加~定量制备好的PAM,继续以lOOrpm的转速搅拌30s, 然后降低搅拌机转速到20~30rpm慢速搅拌60s促进絮凝。分别测定预处置后污泥的比阻、毛细吸水时间(CST)、过滤液的粘度和离心液的粘度。

(2)比阻按考克力(Coackley)提出的实验办法,采用布氏漏斗实验。布氏漏斗的直径为80mm,滤纸采用由70mm定量中速滤纸,实验真空度控制为0.01MPa。实验反复3次取均匀值。

(3)为了降低比阻,进步污泥脱水效果,在污泥脱水前普通均需对污泥中止预处置。污泥预处置的办法有冰冻一冻结预处置、热处置、酸处置、碱处置、石灰预处置和高分子絮凝剂预处置等,其中高分子絮凝剂聚丙烯酰胺(PAM) 预处置是目前国内外采用最普遍的预处置办法。

(4) 聚丙烯酰胺絮凝剂预处置普通占整个污泥处置费用较高的比例,因而,聚丙烯酰胺的优化选择和投加率的合理肯定对降低污泥预处置费用相当关键。对选择聚丙烯酰胺的实验办法的研讨已展开多年,包括比阻、CST值、污泥流变性、分别液粘度、活动电流等。The synthesis and process physical properties of AM polyacrylamide: PAM is prepared by direct reaction of acrylonitrile with water under the action of framework copper catalyst, and then dried by ion exchange polymerization. The process is as follows: catalyst: catalytic hydration CH2 = CHCN + H2 humidity CH2 = CHCONH2 polymerization nCH2 = CHCONH2 - initiator - CH2CHCONH2

Industrial uses of polyacrylamide: Polyacrylamide (PAM) has high molecular weight, good water solubility, adjustable molecular weight, and can introduce various ionic groups to obtain specific properties. Low molecular weight is an effective additive or stabilizer for dispersing materials. High molecular weight is an important flocculant. It can produce hydrophilic and water-insoluble gel, which has good adhesion to many groups of surface and dissolved substances. Because of the above properties, PAM is widely used in flocculation, thickening, drag reduction, glue imitation, bonding, scale inhibition and other fields.

Anionic polyacrylamide can be used in different molecular weights according to different uses and user's requirements for product performance.

In industrial wastewater treatment, especially for suspended particles, coarser, high concentration, positive charged particles, neutral and alkaline wastewater such as iron and steel plant wastewater, electroplating plant wastewater, metallurgical wastewater, coal washing wastewater and other wastewater treatment effect is very good.

In drinking water treatment. The water source of many Waterworks in our country is low in mud and high in mineral content, which is turbid. Although it has been treated by precipitation, it still can not meet the requirements. Flocculants are needed to make the water quality clear. Many waterworks use inorganic flocculants, but the amount of inorganic flocculants is large, resulting in poor effect of sludge increase. Anionic polyacrylamide acrylamide monomer was 0.012%. The molecular weight of anionic PAM was 12.5 million and the content of acrylamide monomer was 0.013%. The concentration of two kinds of PAM is 0.05%. They are used after refrigeration for 24 hours.

(1) PAM pretreatment sludge takes lOml sludge and puts it into a 300 ml beaker. Six-unit mixers are used to mix at 1130 RPM speed for 30 seconds, and then the PAM is added to the sludge quickly and quantitatively. The PAM is stirred at lOOrpm speed for 30 seconds, then the speed of the mixer is reduced to 20-30 rpm and the slow stirring speed is 60 seconds to promote flocculation. The specific resistance of pretreated sludge, capillary water absorption time (CST), the viscosity of filtrate and the viscosity of centrifuge were measured.

(2) The specific resistance is tested by Brinell funnel according to the test method proposed by Coackley. The diameter of Brinell funnel is 80 mm. The filter paper is made of 70 mm medium speed filter paper. The vacuum degree of the test is controlled to 0.01 MPa. The experiment was repeated three times to get the average value.

(3) In order to reduce specific resistance and improve sludge dewatering effect, sludge should be pretreated before sludge dewatering. Sludge pretreatment methods include freeze-thaw pretreatment, heat treatment, acid treatment, alkali treatment, lime pretreatment and polymer flocculant pretreatment. Polymer flocculant polyacrylamide (PAM) pretreatment is the most widely used pretreatment method at home and abroad.

(5)实验研讨标明:投加阳离子型和阴离子型PAM后污泥比阻都降低近2个数量级,显著改善了污泥的脱水性能。阴离子型PAM加率为0.3kg/T干污泥,阳离子聚丙烯酰胺絮凝剂投加率为1.5kg/T于污泥,可见阴离子型PAM的投加率远小于阳离子型PAM的投加率,且阴离子型PAM的价钱约是阳离子型PAM价钱的1/2,故阴离子型PAM可作为自来水厂污泥预处置药剂的首选。

(6)依据CST值变化肯定PAM最投加率与测定比阻得到的最投加率分歧。并且CST值与比阻之间存在线性相关关系,比阻值越大,CST值越大,因而能够采用CST值来近似替代污泥比阻反映污泥的脱水性能。与比阻相比,cST值测定快速、烦琐,不但适用于实验室研讨,还可用于消费现场,快速理解污泥脱水性能的变化,使操作人员及时调楚PAM投加率,俭省药剂费。is used as flocculant, and the dosage is inorganic flocculant. One fiftieth of the flocculants, but the effect is several times to dozens of times that of inorganic flocculants. Especially the polyacrylamide produced by our company, the residual monomers have reached the food grade (less than 0.05%), close to the advanced level abroad, non-toxic, more suitable for the treatment of drinking water, and better for the use of organic pollutants polluted river water and anionic polyacrylamide.

Polyacrylamide is used to recover lost starch and distiller's grains in starch and alcohol factories. At present, the starch in the waste water discharged by many starch factories is very high. After discharging, it affects the environment, wastes resources, and adds PAM to make starch precipitate. The precipitate is filtered by pressure filter to become cake and can be used as feed. A large number of distillers'grains in the alcohol factories are processed by this process. A certain alcohol factory in Heilongjiang Province uses polyacrylamide as flocculant, which recycles the distillers' grains and obtains a great deal of experience. Economic benefits.

Polyacrylamide is used as water shutoff agent for profile control and water shutoff in Oilfield and oil displacement agent for tertiary oil recovery.

Polyacrylamide is used as paper-making additive. PAM is widely used in paper-making. It can be used as long fiber paper-making dispersant, wet and dry reinforcing agent, retention aid, filter aid and flocculant of paper-making wastewater.

The latest type of water treatment agent polyacrylamide, when treating sewage and water in many occasions, the combination of anionic polyacrylamide and cationic polyacrylamide has a very significant and synergistic effect than using one kind of ionic polyacrylamide alone. The ability of PAM to reduce surface tension is much greater than the ability of cations or anions existing alone under the same conditions. For the requirement of low surface tension, both anionic and cationic polyacrylamide need to be used at the same time. If they are used improperly, white precipitates will be produced and the effect of using them will be lost. PAM has the characteristics of amphoteric ions. It can complete the coordination of anions and cations. There is no precipitate on the surface. Especially, it is more convenient to use PAM as a flocculant because of the complex water quality or the changeable nature of water.

The sludge used in sewage pretreatment is taken from the sedimentation tank with Qiantang River water as its source of water, and PAC is used as a flocculant in the water plant. The sludge was naturally concentrated to a solid content of 2.7%-2.8%. The organic matter content in the sludge was 12.1%, SJ content was 52.1%, Al content was determined. The content was 20.2%. There are three types of PAM: cationic, anionic and nonionic. Non-ionic PAM dissolves slowly and is generally not used for sludge pretreatment. Therefore, only two representative cationic polyacrylamides and anionic polyacrylamides are selected in the experiment. The molecular weight of cationic PAM was 12 million and the content of

(7)不管是阳离子聚丙烯酰胺絮凝剂还是阴离子聚丙烯酰胺絮凝剂,随着投加率的增加,滤液和离心液粘度都呈现与比阻和CST值类似的变化规律,呈现了明显的最小值,而且该最小值对应投加率与污泥比阻和CST值实验得加率根本分歧。该办法断定率快速、简单,而且还有可能用作消费上在线控制PAint最 佳投加率的参数,但其在消费上的应用还需做进一步的实验研讨。

。 跟着水解度的添加,羧基阴离子添加,分子链不断伸展,然后有使絮凝作用逐渐增强的作用;一起,聚丙烯酰胺分子的负电性亦逐渐增强,又阻碍了其与负电性的泥沙杂质相吸附,并且在吸附架桥中起 首要作用的活性基团-酰胺基也不断减少,然后跟着水解度的添加,又存在使絮凝作用逐渐变差的要素。 阴离子聚丙烯酰胺作为综合成果:水解比过大,加碱费用较高,水解比过小,又会使反应不足,阴离子型聚丙烯酰胺的混凝或助凝作用较差。 所以阴离子聚丙烯酰胺不一定水解度越高越好,什么都会有个限度,适宜的才是zui优的河南安家净环保是一家专业出产各种水处理药剂,致力于绿色环保可再生资源的继续使用,很多投入了科 研资金,首要产品有聚丙烯酰胺絮凝系列,聚合氯化铝系列,聚合硫酸铁系列,碱式氯化铝等均受到全国客户的一致好评,咱们将一如即往的出产出品质优质的产品来报答客户对咱们一向的支持聚丙烯酰胺生产及市场现状分析,可得以下几点认识:

多人在使用前,都知道需要经过进行小试后确定聚合氯化铝的使用方案后在进行大量的投加使用,其中小试需要得到的有聚合氯化铝的类型、含量、溶解浓度、使用方法等。那么如何进行聚合氯化铝的小试呢?河南环保科技有限公司为您介绍一下。

聚合氯化铝的小试一般是先将聚合氯化铝配置成5%浓度的水溶液来进行实验。通常为了方面可以称取5g的聚合氯化铝固体,然后添加到100ml的水中,就可以配置成聚合氯化铝的水溶液。然后将需要处理的污水进行取样并分配成相同的若干份,然后就可以使用聚合氯化铝进行小试。

用滴管将聚合氯化铝的水溶液慢慢添加到污水中,并使用玻璃棒进行搅拌,观察污水的絮凝效果,如果出现矾花就表示聚合氯化铝的絮凝效果较好,然后将不同的量的聚合氯化铝水溶液添加到污水的样品中,搅拌静置一段时间后观察看哪个污水样品更加干净清澈。在使用聚合氯化铝的过程中,有时候需要添加一些其他的助凝剂如聚丙烯酰胺等,这样会加快污水的絮凝和沉淀达到更加好的处理效果。ties. The flocculation is deteriorated gradually with the addition of hydrolysis degree. Anionic polyacrylamide as a comprehensive result: the hydrolysis ratio is too large, the cost of adding alkali is higher, the hydrolysis ratio is too small, and the reaction will be insufficient, the coagulation or coagulation of anionic polyacrylamide is poor. Therefore, anionic polyacrylamide is not necessarily hydrolyzed higher, the better, everything will have a limit, the appropriate is Zui excellent Henan Anjiajing Environmental Protection is a professional production of various water treatment agents, committed to the continued use of green and environmentally friendly renewable resources, a lot of investment in scientific research funds, the primary product is polyacrylamide flocs. Coagulation series, polyaluminium chloride series, polyferric sulfate series, alkaline aluminium chloride series and so on are all praised by the national customers. We will continue to produce high-quality products to repay customers for our support of the production and market analysis of polyacrylamide, we can get the following understandings:

1、我国已有10个5000t/a以上的PAM生产厂,其中有5个万吨级PAM大厂。这典 厂家占全国年产量的56%,生产的集中度正在提高。PAM全行业的总销售额为62亿元。

2、PAM的主要用途是油田、水处理、造纸三大领域,而且仍然会有增大用量的市场水处理已占整个PAM市场的1/4,并且将会比油田市场的增长速度更快;目前造纸市场比较集中,由四五家PAM厂所占有,其中某些品种有较强的专用性。阳离子型聚丙烯酰胺所占比例只有13%,从水处理市场今后发展来看,阳离子型聚丙烯酰胺的发展都将有更快的增速。

3、目前,PAM产品在我国的能源战略、节水战略中占有重要的地位,是不可缺少的产品,它在我国乃至全世界的能源危机以及下一个更为严重的水资源危机中将会扮演更为积极的角色。

4、由于一些油田淡水资源的缺乏及降低生产成本、环保等方面的要求,三次采油多采用污水配制聚合物,对耐温抗盐聚合物的需求越来越多,子聚丙烯酰胺的趋势,而我国能够生产抗盐聚合物的企业只有三四家,总生产能力在6×104t左右,远远不能满足三次采油的需求,因此,抗盐聚丙烯酰胺具有广阔的应用前景。

There are 10 PAM factories with a capacity of more than 5000t/a in China, of which there are 5 large PAM factories with a capacity of 10,000 tons. This manufacturer accounts for 56% of the country's annual output, and the concentration of production is increasing. The total sales volume of PAM industry is 6.2 billion yuan.

2. The main uses of PAM are oil field, water treatment and papermaking, and there is still room for increasing the amount of PAM. The second largest market, water treatment, has accounted for one fourth of the total PAM market and will grow faster than the oilfield market. At present, the paper-making market is relatively concentrated and occupied by four or five PAM factories, some of which have strong specificity. The proportion of cationic polyacrylamide is only 13%. From the future development of water treatment market, the development of cationic polyacrylamide will have a faster growth rate.

3. At present, PAM products occupy an important position in China's energy strategy and water-saving strategy, and are indispensable products. It will play a more active role in the energy crisis in China and the world as well as in the next more serious water resources crisis.

4. Because of the shortage of freshwater resources in some oilfields and the requirement of reducing production cost and environmental protection, sewage is mostly used to prepare polymers for tertiary oil recovery. There is an increasing demand for temperature-resistant and salt-resistant polymers, which tends to replace polymer polyacrylamide in an all-round way. However, only three or four enterprises in China can produce salt-resistant polymers. The total production capacity of salt-resistant polyacrylamide is about 6 *104t, which can not meet the demand of tertiary oil recovery. Therefore, salt-resistant polyacrylamide has broad application prospects.

In addition, the demand for polyacrylamide products will increase considerably in recent years due to the attention paid by our government and relevant enterprises to sewage treatment. Most domestic enterprises plan to build polyacrylamide projects mainly for urban sewage treatment. According to experts'prediction, the annual demand of municipal wastewater treatment in Shanghai alone will reach 1 x104t. It can be expected that the application potential of polyacrylamide products in wastewater treatment will be tremendous.

It can be seen that salt-resistant polyacrylamide products have broad application prospects in tertiary oil recovery and sewage treatment.

此外,由于近几年关企业对污水处理事业的重视,对聚丙烯酰胺产品的需求量将会有较大幅度的增加。国内大部分企业拟建聚丙烯酰胺项目主要是针对城市污水处理。据,仅上海的城市污水处理年需量将达1×104t,可以预期聚丙烯酰胺产品在 污水处理方面应用的潜为巨大。

由此可见,抗盐聚丙烯酰胺产品在三次采油和污水处理方面的应用前景十分广阔,其他行业的应

从而将处理后饮用水中的磷含量降至界限值以下,不需要改动原水处理流程,不需要增设大型水处理构筑物,简便易行,经济实用,可获得显著的社会和经济效益。

河道治理用的除磷剂运用方法量投加不会造成不良影响的,毕竟铁也是微生物生长所需要的微量元素。但是如果投加量过大,则会使污泥活性收到影响,还有疑问可以到环保.通交流。

生化末端 没有影响,何况少量的铁盐能够对Phosphorus removal agent for road treatment is a kind of material for coagulation and turbidity removal of urban water source and phosphorus removal. It can reach the intent of deep dephosphorization at the same time of coagulation and turbidity removal of urban water source.

Thus, the phosphorus content in treated drinking water can be reduced to below the threshold value, without changing the original water treatment process, without adding large water treatment structures, which is simple, economical and practical, and can achieve remarkable social and economic benefits.

The amount of phosphorus removal agent used in river regulation will not cause adverse effects. After all, iron is also a trace element needed for microbial growth. However, if the dosage is too large, the sludge activity will be affected. There are still doubts about environmental protection and communication.

There is no effect on the biochemical end, let alone a small amount of iron salts.

悬浮物上漂

1、操作不当,有的是不专业的人员在实验中运用了不当手法,加入聚合氯化铝后,搅拌过急过慢都不行,初次实验,要有专业的水处理师从旁协助,这是很重要的一点。

2、加聚合硫酸铁的量没有控制好,(加药过多或过少)这种情况,最容易出现悬浮物上漂。

使用前,将本产品按一定浓度(10-30%)投入溶矾池,注入自来水搅拌使之充分水解,静置至呈红棕色液体,再兑水稀释到所需浓度投加混凝。水厂亦可配成2-5%直接投加,工业废水处理直接配 成5-10%投加。 b、投加量的确定,根据原水性质可通过生产调试或烧杯实验视矾花形成适量而定,制水厂可以原用的其它药剂量作为参考,在同等条件下本产品与固体聚合氯化铝用量大体相当,是固体硫酸铝用量的 1/3-1/4。如果原用的是液体产品,可根据相应药剂浓度计算酌定。大致按重量比1:3而定。

关于污水处理使用聚合硫酸铁上水层出现漂浮物的原因以及解决方法

污水处理1. Improper operation, some non-professional personnel in the experiment used improper techniques, adding polyaluminium chloride, stirring too fast or too slow can not, the first experiment, there must be professional water treatment assistant, this is a very important point.

2. The amount of polyferric sulfate added is not well controlled (too much or too little dosage). In this case, suspended solids are most likely to float.

Before use, the product was put into the alum bath at a certain concentration (10-30%) and stirred with tap water to make it fully hydrolyzed. The product was put into a red-brown liquid and diluted with water until the required concentration was added and coagulated. Waterworks can also be added 2-5% directly, and industrial wastewater treatment can be added 5-10%. B. The determination of dosage depends on the proper amount of alum formed by production debugging or beaker experiment according to the nature of raw water. The other dosage used in water plant can be used as reference. Under the same conditions, the dosage of this product is approximately equal to that of solid polyaluminium chloride, which is 1/3-1/4 of that of solid aluminium sulfate. If the original liquid product is used, it can be calculated according to the concentration of the corresponding agent. It depends roughly on the weight ratio of 1:3.

Reasons and Solutions for Floating Matter in the Upper Water Layer of Polyferric Sulfate Used in Sewage Treatment

3、加聚合硫酸铁的量对了,但是废水的PH值不对,没有在相应药剂的使用PH范围。适应水体PH值范围宽为4-11,H值范围为6-9,净化后原水的PH值与总碱度变化幅度小

4、使用净水产品的型号不对,根据污水的特点,选择适合自己污水特征的净水剂,如:聚合氯化铝、聚氯化铝、聚合氯化铝铁、氯化铝、喷雾式聚合氯化铝、白色聚合氯化铝等等,听从专业水处理师的指导意见,他们给的意见都是专业性的。

关于污水处理使用聚合硫酸铁上水层出现漂浮物的原因以及解决方法

聚合硫酸铁

5、最后一点要考虑的就是,你所使用的聚合硫酸铁,质量是否达标,聚合硫酸铁的各项指标是否符合标准。

现在市面上聚合硫酸铁的质量参差不齐,相对于质量好一些的聚合硫酸铁在使用过程中,出现悬浮物的几率会很低的,好一些的聚合硫酸铁几乎是没有水不溶物的,所以产品质量也是非常重要。微生物活性有促进作用,就是出水色度有影响

将化学除磷剂投加于生化池的后面,这样便可以完全避免水中多种物质与除磷剂发生反应,消耗药剂用量.且不会降低生化池的进水有机碳浓度,影响微生物的脱氮除磷效果。同时还可避免过多投加除磷剂,也会使残余的药剂进入生化系统中,对微生物生长造成影响。

将除磷絮凝剂投加于好氧池的出水口端,二沉池的前面投加除磷剂则可以大量减少除磷药剂的使用量,这是废水在生化处理的过程中已去除水中大部分磷,并将偏磷、有机磷转化为可通过混凝处理的正磷,大大提高除磷效果和减少除磷剂投加量,减少污泥产量、减少污泥中的磷含量。 所以,化学除磷药剂一般投加于生化后,二沉池前,节省废水除磷成本和提高达标率。?

运用时可将本产品直接投加,或先参加溶解罐,浓度为10~20%,拌和,用泵投加到反响池。本产品适用的pH值规模广,在酸性条件下运用效果尤佳,运用量约为100~1000ppm(即0.1~1公斤/吨废水),依据废水中磷酸根的含量不同其用量有所差异,详细用量一般通过试验断定。

试验时取一定量的原水,参加适量的本产品(如500ppm),将废水pH值调节至7~8,www.hnldscl.com参加少数聚丙烯酰胺PAM絮凝沉积,过滤取上清液测定磷的含量。(如需处理重金属,用上清液进行二次处理即可。)AC/PAM与除磷剂搅拌后的反应?使用时可将本产品直接投加,或先参加溶解罐,浓度为10~20%,拌和,用泵投加到反响池。本产品适用的pH值规模广,在酸性条件下使用作用尤佳,使用量约为100~1000ppm(即0.1~1公斤/吨废水),依据废水中磷酸根的含量不同其用量有所差异,具体用量一般经过试验断定。The amount of polyferric sulfate added is right, but the PH value of wastewater is not right, and there is no optimum range of PH used in the corresponding reagents. The suitable range of PH value is 4-11, and the optimum range of PH value is 6-9. After purification, the change range of PH value and total alkalinity of raw water is small.

4, the type of water purification products is not correct. According to the characteristics of sewage, choose suitable water purifying agent suitable for its own sewage characteristics, such as polyaluminum chloride, polyaluminum chloride, polyaluminum ferric chloride, aluminum chloride, spray polyaluminum chloride, white polyaluminium chloride, etc., and listen to the advice of professional water treatment division, and give their advice. They are all professional.

Reasons and Solutions for Floating Matter in the Upper Water Layer of Polyferric Sulfate Used in Sewage Treatment

Polyferric sulfate

5. The last point to consider is whether the quality of the polyferric sulfate you use meets the national standards, and whether the various indicators of the polyferric sulfate meet the national standards.

At present, the quality of polyferric sulfate is uneven in the market. Compared with the better quality of Polyferric sulfate, the probability of suspended solids will be very low. The better polyferric sulfate has almost no water insoluble solids, so the quality of products is also very important. Microbial activity has a promotive effect, that is, effluent color has an impact.

Adding chemical Dephosphorizer to the back of biochemical pond can completely avoid the reaction between various substances in water and dephosphorizer, consume the amount of reagent, and will not reduce the concentration of organic carbon in the influent of biochemical pond, affecting the effect of nitrogen and phosphorus removal by microorganisms. At the same time, it can avoid excessive dosage of phosphorus removal agents, and also make the residual agents into the biochemical system, which will affect the growth of microorganisms.

Adding phosphorus removal flocculant to the outlet of aerobic tank and phosphorus removal agent in front of secondary sedimentation tank can greatly reduce the use of phosphorus removal agent. This is because most phosphorus in wastewater has been removed in the process of biochemical treatment, and phosphorus migration and organic phosphorus are converted into positive phosphorus which can be treated by coagulation, which greatly improves the effect of phosphorus removal and improves the efficiency of phosphorus removal. Reduce the dosage of phosphorus removal agent, reduce sludge production, reduce phosphorus content in sludge. Therefore, chemical phosphorus removal agents are generally added to the biochemical process, before the secondary sedimentation tank, to save the cost of phosphorus removal from wastewater and improve the rate of reaching the standard. ?

When in use, the product can be directly added or participated in the dissolving tank, the concentration of which is 10-20%, mixed and pumped into the reaction tank. The product is suitable for a wide range of pH values, especially in acidic conditions. Its application amount is about 100-1000 ppm (i.e. 0.1-1 kg/ton wastewater). According to the different content of phosphate in wastewater, its dosage is different. The detailed dosage is generally determined by experiments.

During the experiment, a certain amount of raw water was taken and the product (such as 500 ppm) was added. The pH value of the wastewater was adjusted to 7-8. www.hnldscl.com participated in the flocculation and deposition of a few PAM. The supernatant was filtered to determine the phosphorus content. (If heavy metals need to be treated, the supernatant can be used for secondary treatment.) Reaction of AC/PAM with phosphorus removal agent after stirring? When in use, the product can be directly added or participated in the dissolving tank at the concentration of 10-20%. The product can be mixed and pumped into the reaction tank. The product is suitable for a wide range of pH values, especially in acidic conditions. Its usage is about 100-1000ppm (i.e. 0.1-1 kg/ton wastewater). According to the content of phosphate in wastewater, its dosage is different. The specific dosage is generally determined by experiments.

试验时取一定量的原水,参加适量的本产品(如500ppm),将废水pH值调理至7~8,参加少数聚丙烯酰胺PAM絮凝沉积,过滤取上清液测定磷的含量。(如需处理重金属,用上清液进行二次处理即可。) FeCl3、及 AlCl3溶液充沛混合均匀后参加NaOH溶液,三者摩尔比为3∶2∶14;混合反响并静置后滤出生成物,用水重复洗刷至出水为中性;于100-110℃下烘干并制成尺度均匀的粒状吸附剂。

该吸附剂的使用,在惯例水处理工艺中增设吸附除磷工艺,吸附除磷工艺由2-4个串联运转的除磷吸附池组成,除磷吸附池结构同滤池,用粒状复合铁铝除磷吸附剂作滤料,粒径规模0.5mm-0.8mm,吸附层厚度为1.0-1.5m,吸附池水力负荷5m/h-8m/h,空床触摸时刻30-40min。该吸附剂除磷适用规模广;除污染效能优异,再生简略,质料价格低,易得安全。

PAC/PAM与除磷剂制备办法

FeCl3及 AlCl3溶液充沛混合均匀后参加NaOH溶液,三者摩尔比为3∶2∶14;混合反响并静置后滤出生成w物,用水重复洗刷至出水为中性;于100-110℃下烘干并制成尺度均匀的粒状吸附剂。

该吸附剂的使用,在惯例水处理工艺中增设吸附除磷工艺,吸附除磷工艺由2-4个串联运转的除磷吸附池组成,除磷吸附池结构同滤池,用粒状复合铁铝除磷吸附剂作滤料,粒径规模0.5mm-0.8mm,吸附层厚度为1.0-1.5m,吸附池水力负荷5m/h-8m/h,空床触摸时刻30-40min。该吸附剂除磷适用规模广;除污染效能优异,再生简略,质料价格低,易得安In the experiment, a certain amount of raw water was taken and the product (e.g. 500 ppm) was participated in. The pH value of wastewater was adjusted to 7-8. A few PAM flocculating deposits were participated in. The content of phosphorus in the supernatant was determined by filtration. (If heavy metals need to be treated, the supernatant can be used for secondary treatment.) FeCl3, AlCl3 and AlCl3 solutions were mixed in NaOH solution with a molar ratio of 3:2:14; the product was filtered after mixing reaction and standing, and washed repeatedly with water until the effluent was neutral; the granular adsorbent was dried at 100-110 ~C and made into uniform size.

The adsorbent is used to remove phosphorus by adsorption in conventional water treatment process. The adsorbent consists of 2-4 series operation phosphorus removal adsorbents. The structure of the adsorbent is the same as that of the filter. The particle size of the adsorbent is 0.5mm-0.8mm, the thickness of the adsorbent layer is 1.0-1.5m, and the hydraulic force of the adsorbent is negative. Load 5 m/h-8 m/h, empty bed touching time 30-40 min. The adsorbent has wide application scale for phosphorus removal, excellent pollution removal efficiency, simple regeneration, low material price and easy to obtain safety.

Preparation of PAC/PAM and Phosphorus Removal Agent

FeCl3 and AlCl3 solutions were mixed in NaOH solution with a molar ratio of 3:2:14. After mixing and standing, W was filtered and washed repeatedly with water until the effluent was neutral. The granular adsorbent was dried at 100-110 C and made into uniform size.

The adsorbent is used to remove phosphorus by adsorption in conventional water treatment process. The adsorbent consists of 2-4 series operation phosphorus removal adsorbents. The structure of the adsorbent is the same as that of the filter. The particle size of the adsorbent is 0.5mm-0.8mm, the thickness of the adsorbent layer is 1.0-1.5m, and the hydraulic force of the adsorbent is negative. Load 5 m/h-8 m/h, empty bed touching time 30-40 min. The adsorbent is suitable for phosphorus removal on a wide scale, with excellent pollution removal efficiency, simple regeneration, low material price and easy access to safety.

FeCl3、及 AlCl3溶液充分混合均匀后参加NaOH溶液,三者摩尔比为3∶2∶14;混合反响并静置后滤出生成物,用水反复洗刷至出水为中性;于100-110℃下烘干并制成尺度均匀的粒状吸附剂。该吸附剂的使用,在常规水处理工艺中增设吸附除磷工艺,吸附除磷工艺由2-4个串联运转的除磷吸附池组成,除磷吸附池结构同滤池,用粒状复合铁铝除磷吸附剂作滤料,粒径规模0.5mm-0.8mm,吸附层厚度为1.0-1.5m,吸附池水力负荷5m/h-8m/h,空床触摸时间30-40min。该吸附剂除磷适用规模广;除污染效能优异,再生简单,质料价格低,易得安全。

河道治理用的除磷剂适用规模

1、用于生活污水处理厂除磷,特别是合适中磷段污水处理;

2、合适于含外表处理工艺的工业废水;

3、用于食品厂废水;

4、用于制药、造纸、农药、化肥厂的废水处理。

5、用于废物填埋厂废物渗滤液处理。After fully mixing and homogenizing AlCl3 solution, NaOH solution was added with a molar ratio of 3:2:14; the product was filtered after mixing and standing, and washed repeatedly with water until the effluent was neutral; the granular adsorbent was dried at 100-110 (?) C and made into uniform size. The adsorbent is used to remove phosphorus by adsorption in conventional water treatment process. The adsorbent consists of 2-4 series operation phosphorus removal adsorbents. The structure of the adsorbent is the same as that of the filter. The particle size of the adsorbent is 0.5mm-0.8mm, the thickness of the adsorbent layer is 1.0-1.5m, and the hydraulic force of the adsorbent is negative. Load 5 m/h-8 m/h, empty bed touch time 30-40 min. The adsorbent has wide application scale for phosphorus removal, excellent pollution removal efficiency, simple regeneration, low material price and easy safety.

Application Scale of Phosphorus Removal Agents for River Regulation

1. It is used for phosphorus removal in domestic sewage treatment plants, especially for medium phosphorus section sewage treatment.

2. Suitable for industrial wastewater containing surface treatment process.

3. Wastewater from food factories;

4. Wastewater treatment in pharmaceutical, papermaking, pesticide and fertilizer plants.

5. Waste leachate treatment in waste landfill plants.

聚丙烯酰胺工业用处:聚丙烯酸胺(PAM)分子量高、水溶性好、可调理分子量,并能够引进各种离子基团以得到特定的性能。低分子量是分散资料有效增调剂或稳定剂,高分子量是重要的絮凝剂,它能够制造出亲水而水不溶性的凝胶,它对许多团体外表和溶解物质有良可以作为净水药剂使用,也可以在造纸领域被当做助留剂使用,部分造纸使用草浆纤维较短,细胞杂质较高,导致了纸张强度较差,抄纸过程中滤水困难。对于此问题处理办法有两种:机械截留和胶体絮凝。

机械截留类似于过滤作用,它适用于纸张中较长部分纤维,纤细组分隐藏高的原因无法由此说明,助留剂的助留作用也无法用此解释;

胶体絮凝作用为:凝聚作用和絮凝作用。分子量较小或者无机盐、电荷密度较高的聚合物使胶体悬浮液稳定性丧失从而发生絮聚作用称之为凝聚作用,经过电荷中和、异相凝聚和补缀作用几种方法产生的沉积物。聚合氯化铝是指聚凝作用中所提到的无机盐。电荷密度较高的聚合物。

运用聚合氯化铝处理了造纸进程由酸性改为中、碱性规模,纸浆中的阴离子杂质的问题,纸机操作以及纸质量的一系列问题,聚合氯化铝带有阳电荷,可以有效的控制阴离子的作用,有利于纸张滤水性 改善,聚合氯化铝极容易在纤维外表形成吸附,还可以将带有负电荷的填料和纤维吸附,使细料的藏着率有效的提高,浆料的滤水功效得到进一步的改善好的粘附力。由于以上性能PAM普遍应用于絮凝、增稠、减阻、拟胶、粘结、阻垢等范畴 。

阴离子聚丙烯酰胺依据不同用处和用户对产品性能的央求,可选用不同分子量运用。

在工业废水处置中,特别是关于悬浮颗粒、较粗、浓度高、粒子带阳电荷,水的PH值为中性工碱性的污水如钢铁厂废水,电镀厂废水,冶金废水,洗煤废水等污水处置效果很好。

在饮用水处置。我国很多自来水厂的水源自江河泥少及矿物质含量高,比拟混浊,虽经过沉淀处置,但仍达不到央求,需求投加絮凝剂,才干使水质变清,很多自来水厂采用无机絮凝剂,但投加量大,构成污泥量增大效果不好,采用阴离子聚丙烯酰胺作絮凝剂,投加量是无机絮凝的50分之一但效果是无机絮凝剂的几倍至几十倍,特别是我公司消费的聚丙烯酰胺,剩余单体已抵达食品级(小于0.05%),接近国外先进程度,,对处置饮用水更为合适,关于有机物污染严重的江河水和阴离子聚丙烯酰胺配合运用效果更好。

聚丙烯酰胺用作淀粉厂及酒精厂的流失淀粉及酒糟的回收。往常很多淀粉厂排出的废水内淀粉很高,排放之后影响环境,糜费资源,投加PAM,使淀粉沉淀,沉淀物经压滤机压滤变成饼类可作饲料,酒精厂大量的酒糟就是采用这种工艺加工的,黑龙江某酒精厂就是聚丙烯酰胺作絮凝剂,对酒糟中止回收的而且获得了很大的经济效益。

聚丙烯酰胺用作油田调剖堵水的堵水剂,三次采油的驱油剂。

聚丙烯酰胺用作造纸助剂,PAM在造纸方面用处很普遍,可作为长纤维造纸分散剂,干湿加强剂,助留,助滤剂及造纸废水的絮凝剂等。

最新型的水处置剂聚丙烯酰胺,在很多场所处置污水和上水时,阴离子聚丙烯酰胺和阳离子聚丙烯酰胺配合运用要比单独运用一种离子型聚丙烯酰胺产生十分显著和协同效应,PAM对降低外表张力的才干要远远大于同条件下阳离子或阴离子单独存在的才干,为抵达降低外表张力的央求,需求同时运用阴离子和阳离子聚丙烯酰胺,便两者如运用不当,会产生白色沉淀物,失去运用效果 。而PAM具有两性离子的特性,它能够完成阴离子、阳离子的配合协同作用,面没有任何沉淀物的产生,特别是对水质状况比拟复杂或水的性质经常变化的,运用PAM作为处置絮凝剂更为便当,效果更好。

在污水预处置中采用的污泥取自以钱塘江水为水源的沉淀池,该水厂以聚合氯化铝PAC为絮凝剂。污泥经自然浓缩到含固率为2.7%~2.8%,经测定,污泥中有机物含量为12.1%,sj如含量为52.1%,Al。含量为20.2%。 PAM有阳离子型、阴离子型和非离子型三品种型。非离子型PAM溶解速度较慢,普通不用于污泥预处置,因而实验仅选用两种有代表性的阳离子聚丙烯酰胺和阴离子聚丙烯酰胺。阳离子型PAM分子量1200万,丙烯酰胺单体含量0.012%。阴离子型PAM分子量1250万,丙烯酰胺单体含量0.013%。两种PAM配制浓度均为0.05%%,冰箱冷藏24h后运用。

(1)PAM预处置污泥取lOOml污泥,放入300ml的烧杯中,采用六联搅拌机以1130rpm的转速快 速搅拌30s后疾速投加~定量制备好的PAM,继续以lOOrpm的转速搅拌30s, 然后降低搅拌机转速到20~30rpm慢速搅拌60s促进絮凝。分别测定预处置后污泥的比阻、毛细吸水时间(CST)、过滤液的粘度和离心液的粘度。

(2)比阻按考克力(Coackley)提出的实验办法,采用布氏漏斗实验。布氏漏斗的直径为80mm,滤纸采用由70mm定量中速滤纸,实验真空度控制为0.01MPa。实验反复3次取均匀值。

(3)为了降低比阻,进步污泥脱水效果,在污泥脱水前普通均需对污泥中止预处置。污泥预处置的办法有冰冻一冻结预处置、热处置、酸处置、碱处置、石灰预处置和高分子絮凝剂预处置等,其中高分子絮凝剂聚丙烯酰胺(PAM) 预处置是目前国内外采用最普遍的预处置办法。

(4) 聚丙烯酰胺絮凝剂预处置普通占整个污泥处置费用较高的比例,因而,聚丙烯酰胺的优化选择和投加率的合理肯定对降低污泥预处置费用相当关键。对选择聚丙烯酰胺的实验办法的研讨已展开多年,包括比阻、CST值、污泥流变性、分别液粘度、活动电流等。The synthesis and process physical properties of AM polyacrylamide: PAM is prepared by direct reaction of acrylonitrile with water under the action of framework copper catalyst, and then dried by ion exchange polymerization. The process is as follows: catalyst: catalytic hydration CH2 = CHCN + H2 humidity CH2 = CHCONH2 polymerization nCH2 = CHCONH2 - initiator - CH2CHCONH2

Industrial uses of polyacrylamide: Polyacrylamide (PAM) has high molecular weight, good water solubility, adjustable molecular weight, and can introduce various ionic groups to obtain specific properties. Low molecular weight is an effective additive or stabilizer for dispersing materials. High molecular weight is an important flocculant. It can produce hydrophilic and water-insoluble gel, which has good adhesion to many groups of surface and dissolved substances. Because of the above properties, PAM is widely used in flocculation, thickening, drag reduction, glue imitation, bonding, scale inhibition and other fields.

Anionic polyacrylamide can be used in different molecular weights according to different uses and user's requirements for product performance.

In industrial wastewater treatment, especially for suspended particles, coarser, high concentration, positive charged particles, neutral and alkaline wastewater such as iron and steel plant wastewater, electroplating plant wastewater, metallurgical wastewater, coal washing wastewater and other wastewater treatment effect is very good.

In drinking water treatment. The water source of many Waterworks in our country is low in mud and high in mineral content, which is turbid. Although it has been treated by precipitation, it still can not meet the requirements. Flocculants are needed to make the water quality clear. Many waterworks use inorganic flocculants, but the amount of inorganic flocculants is large, resulting in poor effect of sludge increase. Anionic polyacrylamide acrylamide monomer was 0.012%. The molecular weight of anionic PAM was 12.5 million and the content of acrylamide monomer was 0.013%. The concentration of two kinds of PAM is 0.05%. They are used after refrigeration for 24 hours.

(1) PAM pretreatment sludge takes lOml sludge and puts it into a 300 ml beaker. Six-unit mixers are used to mix at 1130 RPM speed for 30 seconds, and then the PAM is added to the sludge quickly and quantitatively. The PAM is stirred at lOOrpm speed for 30 seconds, then the speed of the mixer is reduced to 20-30 rpm and the slow stirring speed is 60 seconds to promote flocculation. The specific resistance of pretreated sludge, capillary water absorption time (CST), the viscosity of filtrate and the viscosity of centrifuge were measured.

(2) The specific resistance is tested by Brinell funnel according to the test method proposed by Coackley. The diameter of Brinell funnel is 80 mm. The filter paper is made of 70 mm medium speed filter paper. The vacuum degree of the test is controlled to 0.01 MPa. The experiment was repeated three times to get the average value.

(3) In order to reduce specific resistance and improve sludge dewatering effect, sludge should be pretreated before sludge dewatering. Sludge pretreatment methods include freeze-thaw pretreatment, heat treatment, acid treatment, alkali treatment, lime pretreatment and polymer flocculant pretreatment. Polymer flocculant polyacrylamide (PAM) pretreatment is the most widely used pretreatment method at home and abroad.

(5)实验研讨标明:投加阳离子型和阴离子型PAM后污泥比阻都降低近2个数量级,显著改善了污泥的脱水性能。阴离子型PAM加率为0.3kg/T干污泥,阳离子聚丙烯酰胺絮凝剂投加率为1.5kg/T于污泥,可见阴离子型PAM的投加率远小于阳离子型PAM的投加率,且阴离子型PAM的价钱约是阳离子型PAM价钱的1/2,故阴离子型PAM可作为自来水厂污泥预处置药剂的首选。

(6)依据CST值变化肯定PAM最投加率与测定比阻得到的最投加率分歧。并且CST值与比阻之间存在线性相关关系,比阻值越大,CST值越大,因而能够采用CST值来近似替代污泥比阻反映污泥的脱水性能。与比阻相比,cST值测定快速、烦琐,不但适用于实验室研讨,还可用于消费现场,快速理解污泥脱水性能的变化,使操作人员及时调楚PAM投加率,俭省药剂费。is used as flocculant, and the dosage is inorganic flocculant. One fiftieth of the flocculants, but the effect is several times to dozens of times that of inorganic flocculants. Especially the polyacrylamide produced by our company, the residual monomers have reached the food grade (less than 0.05%), close to the advanced level abroad, non-toxic, more suitable for the treatment of drinking water, and better for the use of organic pollutants polluted river water and anionic polyacrylamide.

Polyacrylamide is used to recover lost starch and distiller's grains in starch and alcohol factories. At present, the starch in the waste water discharged by many starch factories is very high. After discharging, it affects the environment, wastes resources, and adds PAM to make starch precipitate. The precipitate is filtered by pressure filter to become cake and can be used as feed. A large number of distillers'grains in the alcohol factories are processed by this process. A certain alcohol factory in Heilongjiang Province uses polyacrylamide as flocculant, which recycles the distillers' grains and obtains a great deal of experience. Economic benefits.

Polyacrylamide is used as water shutoff agent for profile control and water shutoff in Oilfield and oil displacement agent for tertiary oil recovery.

Polyacrylamide is used as paper-making additive. PAM is widely used in paper-making. It can be used as long fiber paper-making dispersant, wet and dry reinforcing agent, retention aid, filter aid and flocculant of paper-making wastewater.

The latest type of water treatment agent polyacrylamide, when treating sewage and water in many occasions, the combination of anionic polyacrylamide and cationic polyacrylamide has a very significant and synergistic effect than using one kind of ionic polyacrylamide alone. The ability of PAM to reduce surface tension is much greater than the ability of cations or anions existing alone under the same conditions. For the requirement of low surface tension, both anionic and cationic polyacrylamide need to be used at the same time. If they are used improperly, white precipitates will be produced and the effect of using them will be lost. PAM has the characteristics of amphoteric ions. It can complete the coordination of anions and cations. There is no precipitate on the surface. Especially, it is more convenient to use PAM as a flocculant because of the complex water quality or the changeable nature of water.

The sludge used in sewage pretreatment is taken from the sedimentation tank with Qiantang River water as its source of water, and PAC is used as a flocculant in the water plant. The sludge was naturally concentrated to a solid content of 2.7%-2.8%. The organic matter content in the sludge was 12.1%, SJ content was 52.1%, Al content was determined. The content was 20.2%. There are three types of PAM: cationic, anionic and nonionic. Non-ionic PAM dissolves slowly and is generally not used for sludge pretreatment. Therefore, only two representative cationic polyacrylamides and anionic polyacrylamides are selected in the experiment. The molecular weight of cationic PAM was 12 million and the content of

(7)不管是阳离子聚丙烯酰胺絮凝剂还是阴离子聚丙烯酰胺絮凝剂,随着投加率的增加,滤液和离心液粘度都呈现与比阻和CST值类似的变化规律,呈现了明显的最小值,而且该最小值对应投加率与污泥比阻和CST值实验得加率根本分歧。该办法断定率快速、简单,而且还有可能用作消费上在线控制PAint最 佳投加率的参数,但其在消费上的应用还需做进一步的实验研讨。

。 跟着水解度的添加,羧基阴离子添加,分子链不断伸展,然后有使絮凝作用逐渐增强的作用;一起,聚丙烯酰胺分子的负电性亦逐渐增强,又阻碍了其与负电性的泥沙杂质相吸附,并且在吸附架桥中起 首要作用的活性基团-酰胺基也不断减少,然后跟着水解度的添加,又存在使絮凝作用逐渐变差的要素。 阴离子聚丙烯酰胺作为综合成果:水解比过大,加碱费用较高,水解比过小,又会使反应不足,阴离子型聚丙烯酰胺的混凝或助凝作用较差。 所以阴离子聚丙烯酰胺不一定水解度越高越好,什么都会有个限度,适宜的才是zui优的河南安家净环保是一家专业出产各种水处理药剂,致力于绿色环保可再生资源的继续使用,很多投入了科 研资金,首要产品有聚丙烯酰胺絮凝系列,聚合氯化铝系列,聚合硫酸铁系列,碱式氯化铝等均受到全国客户的一致好评,咱们将一如即往的出产出品质优质的产品来报答客户对咱们一向的支持聚丙烯酰胺生产及市场现状分析,可得以下几点认识:

多人在使用前,都知道需要经过进行小试后确定聚合氯化铝的使用方案后在进行大量的投加使用,其中小试需要得到的有聚合氯化铝的类型、含量、溶解浓度、使用方法等。那么如何进行聚合氯化铝的小试呢?河南环保科技有限公司为您介绍一下。

聚合氯化铝的小试一般是先将聚合氯化铝配置成5%浓度的水溶液来进行实验。通常为了方面可以称取5g的聚合氯化铝固体,然后添加到100ml的水中,就可以配置成聚合氯化铝的水溶液。然后将需要处理的污水进行取样并分配成相同的若干份,然后就可以使用聚合氯化铝进行小试。

用滴管将聚合氯化铝的水溶液慢慢添加到污水中,并使用玻璃棒进行搅拌,观察污水的絮凝效果,如果出现矾花就表示聚合氯化铝的絮凝效果较好,然后将不同的量的聚合氯化铝水溶液添加到污水的样品中,搅拌静置一段时间后观察看哪个污水样品更加干净清澈。在使用聚合氯化铝的过程中,有时候需要添加一些其他的助凝剂如聚丙烯酰胺等,这样会加快污水的絮凝和沉淀达到更加好的处理效果。ties. The flocculation is deteriorated gradually with the addition of hydrolysis degree. Anionic polyacrylamide as a comprehensive result: the hydrolysis ratio is too large, the cost of adding alkali is higher, the hydrolysis ratio is too small, and the reaction will be insufficient, the coagulation or coagulation of anionic polyacrylamide is poor. Therefore, anionic polyacrylamide is not necessarily hydrolyzed higher, the better, everything will have a limit, the appropriate is Zui excellent Henan Anjiajing Environmental Protection is a professional production of various water treatment agents, committed to the continued use of green and environmentally friendly renewable resources, a lot of investment in scientific research funds, the primary product is polyacrylamide flocs. Coagulation series, polyaluminium chloride series, polyferric sulfate series, alkaline aluminium chloride series and so on are all praised by the national customers. We will continue to produce high-quality products to repay customers for our support of the production and market analysis of polyacrylamide, we can get the following understandings:

1、我国已有10个5000t/a以上的PAM生产厂,其中有5个万吨级PAM大厂。这典 厂家占全国年产量的56%,生产的集中度正在提高。PAM全行业的总销售额为62亿元。

2、PAM的主要用途是油田、水处理、造纸三大领域,而且仍然会有增大用量的市场水处理已占整个PAM市场的1/4,并且将会比油田市场的增长速度更快;目前造纸市场比较集中,由四五家PAM厂所占有,其中某些品种有较强的专用性。阳离子型聚丙烯酰胺所占比例只有13%,从水处理市场今后发展来看,阳离子型聚丙烯酰胺的发展都将有更快的增速。

3、目前,PAM产品在我国的能源战略、节水战略中占有重要的地位,是不可缺少的产品,它在我国乃至全世界的能源危机以及下一个更为严重的水资源危机中将会扮演更为积极的角色。

4、由于一些油田淡水资源的缺乏及降低生产成本、环保等方面的要求,三次采油多采用污水配制聚合物,对耐温抗盐聚合物的需求越来越多,子聚丙烯酰胺的趋势,而我国能够生产抗盐聚合物的企业只有三四家,总生产能力在6×104t左右,远远不能满足三次采油的需求,因此,抗盐聚丙烯酰胺具有广阔的应用前景。

There are 10 PAM factories with a capacity of more than 5000t/a in China, of which there are 5 large PAM factories with a capacity of 10,000 tons. This manufacturer accounts for 56% of the country's annual output, and the concentration of production is increasing. The total sales volume of PAM industry is 6.2 billion yuan.

2. The main uses of PAM are oil field, water treatment and papermaking, and there is still room for increasing the amount of PAM. The second largest market, water treatment, has accounted for one fourth of the total PAM market and will grow faster than the oilfield market. At present, the paper-making market is relatively concentrated and occupied by four or five PAM factories, some of which have strong specificity. The proportion of cationic polyacrylamide is only 13%. From the future development of water treatment market, the development of cationic polyacrylamide will have a faster growth rate.

3. At present, PAM products occupy an important position in China's energy strategy and water-saving strategy, and are indispensable products. It will play a more active role in the energy crisis in China and the world as well as in the next more serious water resources crisis.

4. Because of the shortage of freshwater resources in some oilfields and the requirement of reducing production cost and environmental protection, sewage is mostly used to prepare polymers for tertiary oil recovery. There is an increasing demand for temperature-resistant and salt-resistant polymers, which tends to replace polymer polyacrylamide in an all-round way. However, only three or four enterprises in China can produce salt-resistant polymers. The total production capacity of salt-resistant polyacrylamide is about 6 *104t, which can not meet the demand of tertiary oil recovery. Therefore, salt-resistant polyacrylamide has broad application prospects.

In addition, the demand for polyacrylamide products will increase considerably in recent years due to the attention paid by our government and relevant enterprises to sewage treatment. Most domestic enterprises plan to build polyacrylamide projects mainly for urban sewage treatment. According to experts'prediction, the annual demand of municipal wastewater treatment in Shanghai alone will reach 1 x104t. It can be expected that the application potential of polyacrylamide products in wastewater treatment will be tremendous.

It can be seen that salt-resistant polyacrylamide products have broad application prospects in tertiary oil recovery and sewage treatment.

此外,由于近几年关企业对污水处理事业的重视,对聚丙烯酰胺产品的需求量将会有较大幅度的增加。国内大部分企业拟建聚丙烯酰胺项目主要是针对城市污水处理。据,仅上海的城市污水处理年需量将达1×104t,可以预期聚丙烯酰胺产品在 污水处理方面应用的潜为巨大。

由此可见,抗盐聚丙烯酰胺产品在三次采油和污水处理方面的应用前景十分广阔,其他行业的应

在线询盘/留言